ROBOT CONTROL SYSTEM

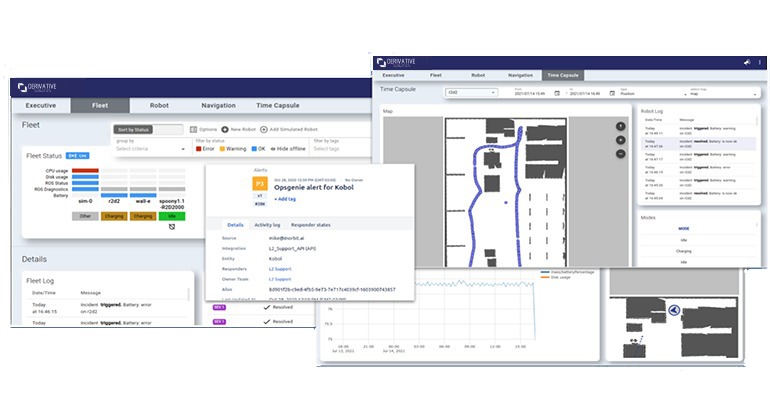

DERIVATIVE Fleet Manager is the ultimate way to control your robots from anywhere. All you need is a smart device! Our fleet management software supplies you with all the information you need to operate your fleet with ease. Think of our software as your fleet’s control center. It connects in real time so it will always give you the most up-to-date information

Maintaining effective logistics and keeping the supply chain moving are more critical than ever. Changing consumer habits are shifting demand across different channels. The explosive growth of e-commerce due to ongoing trends and the recent COVID-19 pandemic are challenging in-house logistics operators and third-party logistics providers to grow capacity and drive efficiency while operating on thin margins. Key areas of focus include:

Productivity

Driving costs down and improving margins.

Resilience

Responding to changing market conditions.

Labor

Availability, cost, health and churn.

Forward-thinking operators are turning to advanced automation for repetitive tasks, such as material handling and order-fulfilment. A traditional fixed infrastructure, such as conveyor belts and other machinery, requires a significant upfront investment and tends to be inflexible. Instead, we are now seeing rapid adoption of Autonomous Mobile Robots (AMRs). These are available from many vendors, and come in several shapes and functions — from small tote carts to pallet stackers and tuggers with payloads up to 15,000 lbs.

But with any technology, this creates its own set of challenges. While AMRs are increasingly flexible, they still encounter situations that a robot’s on-board software can’t resolve on its own. In addition, computer vision and other algorithms occasionally produce false positives. Lastly, the flow of goods within a warehouse or distribution center is constantly changing, which requires a flexible and adaptable solution.

Keeping Tabs on Robots

DERIVATIVE can help warehouse operators relying on AMRs to keep tabs on the robots and empower employees — whether they are across the warehouse or in a remote operations center — to take actions that keep operations flowing smoothly. Our platform can acquire, analyse and process massive amounts of operational data to understand how robots are performing; notify the right people in real-time and respond to incidents as they occur; and enable continuous improvements to the robot software in order to drive operational metrics.

Working with DERIVATIVE platform, we can give your operation:

- Consistent access to heterogeneous robot fleets;

- Fleet-wide performance visibility and analytics;

- Efficient remote and on-site incident resolution;

- Collaboration between human associates and machines;

- Improved metrics, including mean-time to resolution (MTTR), total cost of ownership (TCO) and service-level agreements (SLAs);

- A dedicated customer success team.

STRATEGIC MULTI-ROBOT COLLABORATION

Multi-robot deployments can sometimes lead to confusion and inefficiencies, but DERIVATIVE Fleet Manager knows how to optimize even large deployments with many robots. Every robot has different features that make them suited for certain tasks better than others. Our software knows how to allocate tasks to the robot that will produce the best results. When every robot is doing its part to make your operation thrive, you can expect maximum efficiency.

Optimized Traffic Flow

DERIVATIVE takes traffic management very seriously. That’s why we impose traffic regulations on our robots similar to those imposed on automobiles. Robots must adhere to speed limits, one-way zones, stop signs, and restricted areas. You even have the power to draw virtual lines that your robots must stay on as they move between stations. You won’t have to worry about robots running into each other, blocking work areas, or getting in the way of your employees. Things can operate smoothly.

Area-based control is a vital part of traffic management. Each robot in your fleet can reserve the area they need to be in. While one robot is using an area, no other robot can enter that space. The space is “locked.” If that locked space is another robot’s target station, they must travel to an alternative station instead. All the work gets done in the safest and most cost-effective way.

Of course, robots may need to cross paths. Because of this, our fleet management software also has intersection management to direct robots through congested areas. This ensures that robots are given the ability to proceed at intersections based on the priority of their jobs. Time-sensitive tasks will be completed promptly but without creating a safety hazard in your warehouse.

Advanced Task Monitoring

The DERIVATIVE Fleet Manager will never randomly assign a task to a robot. It takes many factors into account to delegate intelligently. By monitoring battery life, workload, location, and other parameters, this system can find the robot that’s right for the task. Because of our advanced algorithm, every robot in your fleet will work together seamlessly.

Our fleet management software allows you to plan ahead with your fleet, scheduling future tasks. Tasks may also have dependencies. Although these configurations may sound complex, they can be generated with ease using our mission planner. Our drag-and-drop user interface helps you customize automation workflows directly. You never have to code or use third-party integrators!

REAL-TIME FLEET MONITORING

You can track all aspects of your fleet through our easy-to-use interface. When you use the DERIVATIVE Fleet Manager dashboards, you can empower different groups to supervise and deploy robots. You can monitor vehicle information, check robot health, and track the flow of materials from any mobile device. Toggle between map and status views so you’re always in the know about your robots and materials.

DERIVATIVE doesn’t want you to have to go sifting through data to find the metrics that you need. That’s why we don’t just send alerts on time-sensitive material movement needs. We also send you smart notifications on key information such as throughput, distance, job takt times, and more. You can put minimal time and effort into staying informed.

All this info and more is right at your fingertips! When you’re able to continuously monitor every robot in your fleet, you will experience increased productivity and optimized material flow.

SEAMLESS INTEGRATION PROCESS

Integrating a new software is often complicated, but with DERIVATIVE Fleet Management and our custom tools, it’s simple. Because of our superior flexibility and powerful REST API, we can integrate with any WMS/MES or custom system. This allows you to create new tasks procedures in an automated way without using your software’s user interface.

The DERIVATIVE Fleet Manager is also compatible with PLC and OPC-UA systems. You’ll have all the sensor readings you need right at your fingertips and be able to activate jobs with powerful data. You shouldn’t have any problems using our fleet management system in conjunction with co-bots or other devices you’re using for materials handling.

CUTTING-EDGE REPOTING TOOLS

Each robot generates a massive amount of data. This is a tremendous asset to choosing DERIVATIVE for your robots, but keeping track of all this data can also create more work for you and your employees.

Luckily, the DERIVATIVE Fleet Manager not only records data but also provides you with meaningful insights on your data. We record utilization rates, task failure rates, distances travelled, and processed orders. Our reports are easy to understand and provide you with key information you need to not only run your business but continuously improve it. Because we store data, you can also observe trends over time and identify areas for improvement. When used properly, our cutting-edge reporting tools lead to a strong return on investment.